New analysis from Hydate argues that the future of green hydrogen depends heavily on improving electrolyser efficiency, warning that without such gains, production costs are likely to remain too high for widespread commercial competitiveness.

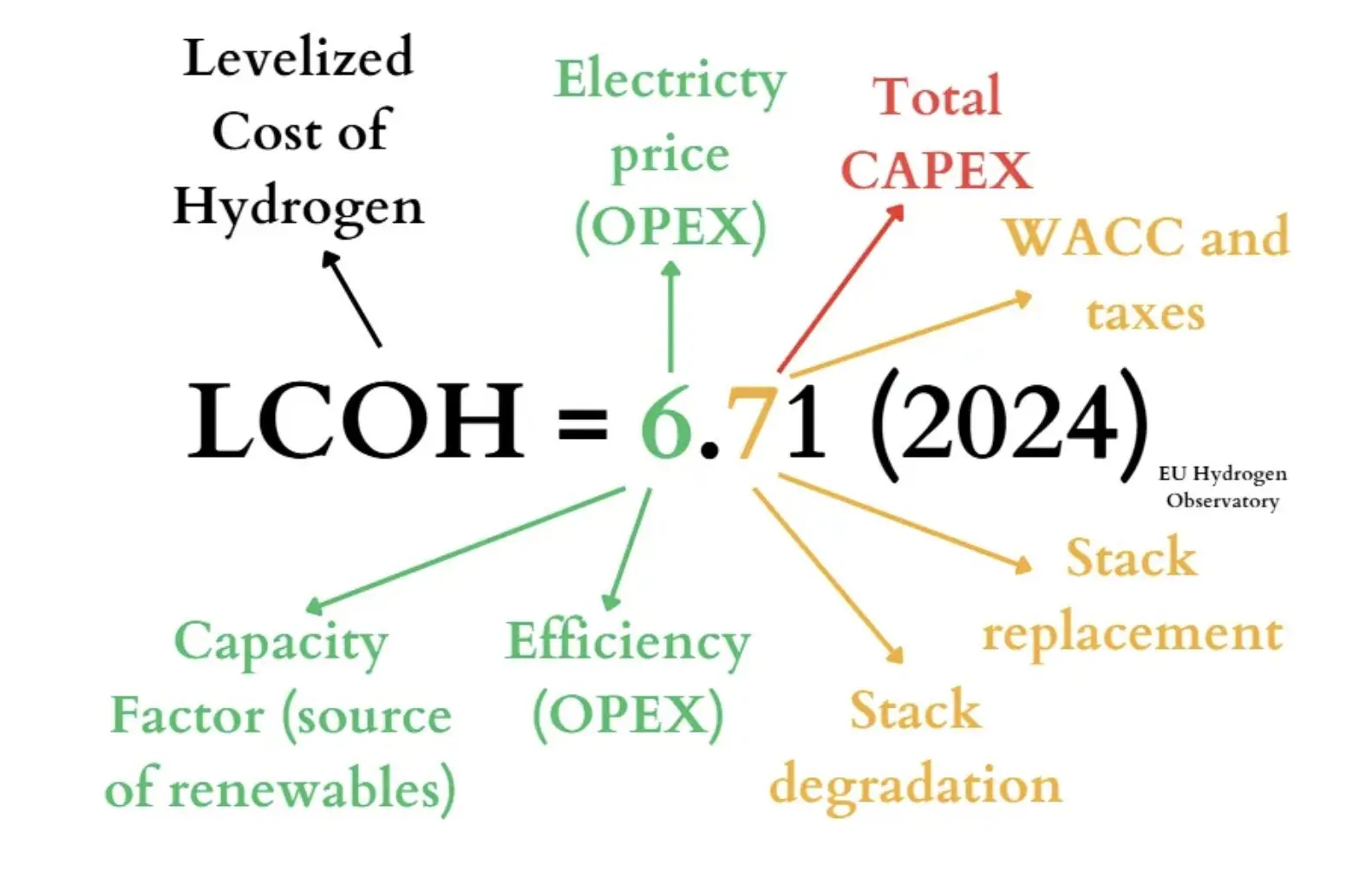

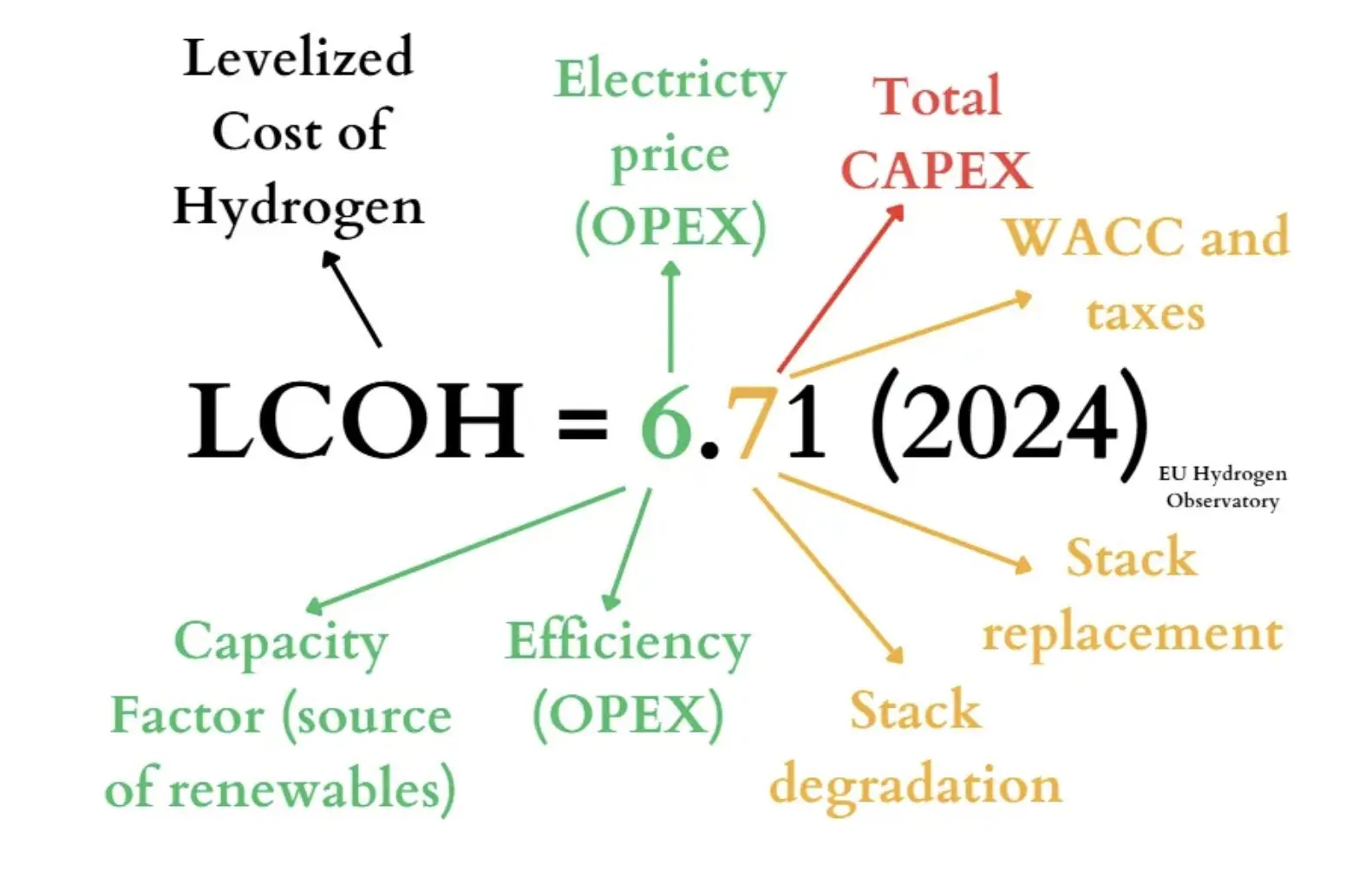

The article stresses that the decisive metric for developers is the Levelised Cost of Hydrogen (LCOH), which reflects both capital costs and, crucially, operating costs — most notably the amount of electricity required to produce each kilogram of hydrogen.

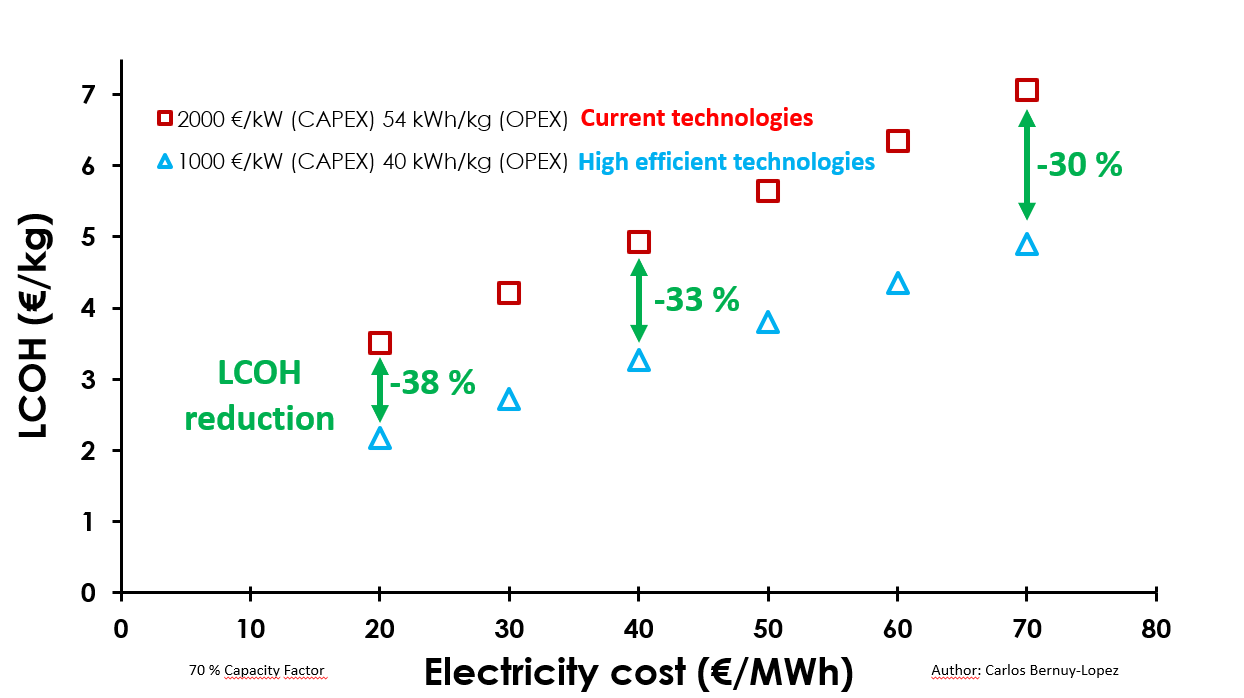

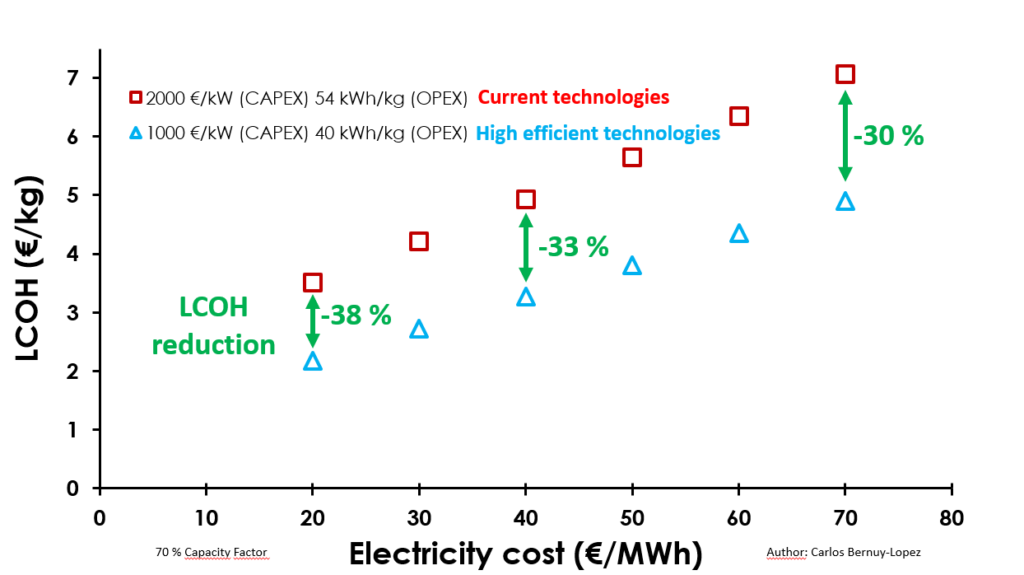

Hydate’s modelling suggests that improvements in electrolyser efficiency could reduce overall production costs by around 38%, largely because more efficient systems need significantly less power per unit of hydrogen produced.

Given that electricity is typically the largest recurring expense in green hydrogen projects, efficiency gains have an outsized impact on competitiveness.

Solid Oxide Electrolysis (SOEC) is highlighted as one of the most promising high-efficiency technologies, though the author notes that low-temperature electrolysers are also improving and may deliver meaningful efficiency gains over time.

The central warning is clear: without greater efficiency, green hydrogen is likely to remain too costly for many industrial applications, making projects harder to finance and slowing large-scale deployment.

Source: Hydate