French industrial gas firm Air Liquide has taken a final investment decision (FID) to build a 200MW electrolysis plant at the Dutch port of Rotterdam.

The ELYgator project at the port’s Maasvlakte site will produce around 23,000 t/yr of renewable hydrogen. Of this, 15,000 t/yr is earmarked for TotalEnergies’ 338,000 b/d Antwerp refinery in Belgium under a supply agreement signed in February. Both the plant and the supply deal are scheduled to begin in late 2027.

Air Liquide estimates the project will cost more than €500mn, with a significant share covered by public funding. The EU awarded €99mn to ELYgator under its 2020 Innovation Fund call, while the Dutch government selected it for €150mn in subsidies through the Hy2Use round of the EU’s Important Projects of Common European Interest (IPCEI) scheme. Last week, the project was also named among 11 winners in the Netherlands’ second subsidy round for electrolysis, although the funding amount has not been disclosed.

The “crucial support” from the tender, combined with earlier subsidy awards and a “refined regulatory framework,” enabled the company to move forward, Air Liquide said.

ELYgator was originally planned for Terneuzen in the southern Netherlands, but was later relocated to Rotterdam.

The project will be the first in the country to integrate both proton exchange membrane (PEM) and alkaline electrolysis technologies at a single site, according to Air Liquide. A 2021 project plan indicated the 200MW capacity would be split evenly between the two. The PEM stacks will be supplied by Air Liquide’s joint venture with Germany’s Siemens Energy, while the supplier for the alkaline systems has not been disclosed.

ELYgator is the joint-largest Dutch electrolysis project to reach FID, alongside Shell’s 200MW Holland Hydrogen 1, also located in the Maasvlakte area and already under construction.

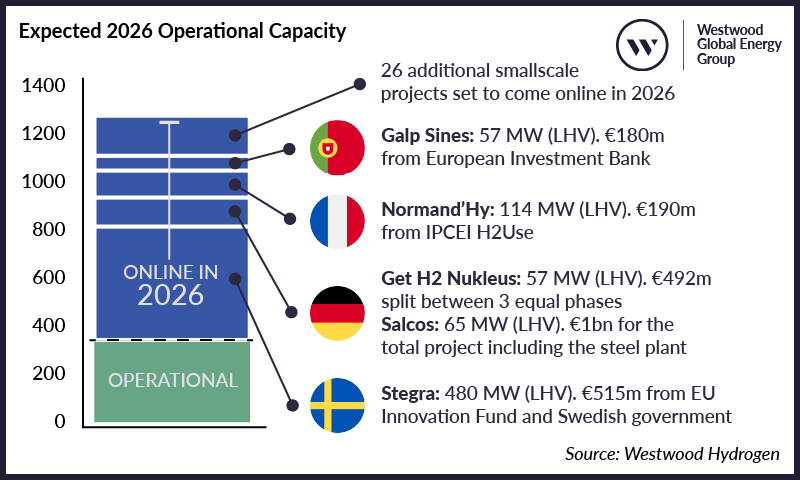

Air Liquide also took FID last year on the 200MW Normand’Hy project in France.

Only three larger green hydrogen projects in Europe have reached FID to date: Stegra’s 700MW plant in Boden, Sweden, for hydrogen-based iron and steelmaking, and two German projects — RWE’s 300MW electrolyser and EWE’s 320MW facility.

Source: Stefan Krumpelmann, Argus Media