China Baowu Steel Group Corporation (Baowu Steel,or Baowu) announced that its subsidiary Zhanjiang Iron and Steel Zero-Carbon Demonstration Plant’s 1 million ton hydrogen-based shaft furnace began production on Dec 23th 2023.

This is the first 1 mnt hydrogen-based shaft furnace in China, and also the first integrated facility for use of hydrogen and coke oven gas for industrial purposes. Compared with tradition coke-based facility, this plant could reduce 500,000 ton CO2 emissions per annum, according to the company.

The construction of this project started on Feb 15th, 2022 and the hydrogen shaft was installed in April 2023.

Photo: 1 million ton hydrogen-based shaft furnace in Baowu Steel Zhanjiang

Photo: 1 million ton hydrogen-based shaft furnace in Baowu Steel Zhanjiang

Currently, the hydrogen is sourced from coke oven gas of 1#, 2#, 3# traditional furnace within the Zhanjiangsteel complex, while Baosteel has a long-term plan to develop low carbon hydrogen supply to achieve ultra-low emission iron and steel production, including hydrogen produced from natural gas or wind power.

China Baowu Steel Group Corporation, headquartered in Shanghai, is a state-owned enterprise directly administrated by the central government. Baowu is the world’s largest steel enterprise, ranking 44th among the Fortune Global 500 in the world. In 2022, China Baowu produced 132 million tons of steel and recorded a total operating income of RMB1.16 trillion.

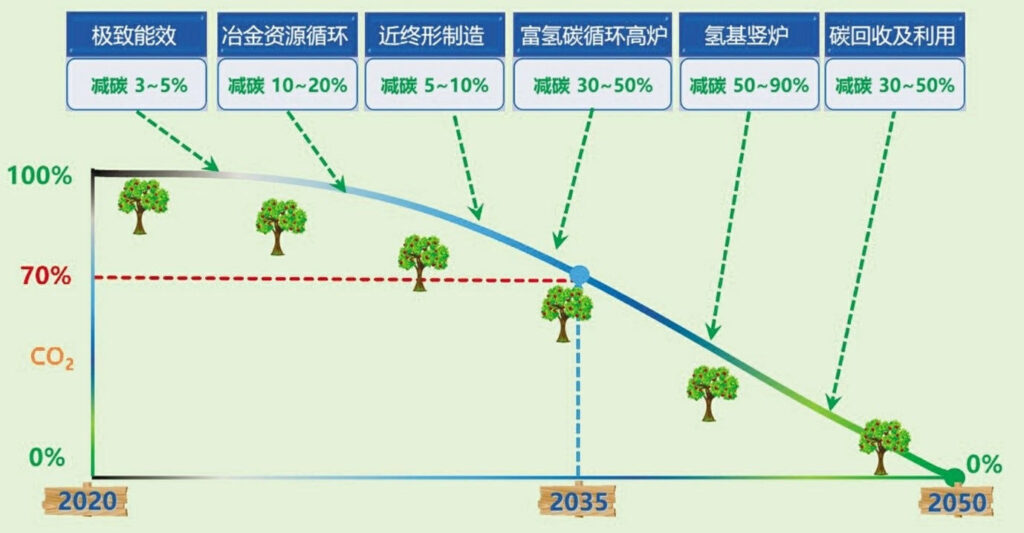

Baowu has released its carbon reduction target in 2021, stated that it will achieve carbon peak by 2023, reduce carbon emission by 30% by 2035, and achieve carbon neutral by 2050. Hydrogen-based shaft is regarded as a promising and practical technology to achieve carbon peak and carbon neutral.

Figure: roadmap and technology choice of Baowu’s carbon reduction

Figure: roadmap and technology choice of Baowu’s carbon reduction

China’s steel industry account for about 17% of national carbon emissions, or over 2 billiion ton per annum. If considered as a country, China’s steel sector is the 5th largest GHG emitter globally. China has focused on reducing excess capacity in the steel industry in recent years, requiring implementation of equal or reduced replacement for new steel production capacities and encouraging the transition to green and low-carbon technologies.

On the basis of the “Opinions on Resolving Excess Capacity and Achieving Development of the Steel Industry” released by the State Council in 2016, the Ministry of Industry and Information Technology officially released the “Measures for Production Replacement in the Steel Industry” in mid-2021, explicitly indicating that the capacity replacement could be prioritized for “non-blast furnace solutions such as hydrogen-based steelmaking” to ensure equal capacity replacement.

Then in Feb 2022, The Ministry of Industry and Information Technology, the National Development and Reform Commission, and the Ministry of Ecology and Environment jointly issued the “Guiding Opinions on Promoting the High-quality Development of the Iron and Steel Industry” and “Guidelines for the Implementation of Energy Saving and Carbon Reduction Transformation and Upgrading of the Steel Industry”, China’s policy-makers are seeking to decarbonize domestic steel industry while maintain their competitiveness.

A number of leading Chinese steel companies have also started hydrogen-based steelmaking pilot demonstration projects, including Bayi Steel Company’s hydrogen-rich carbon cycle blast furnace pilot project, Baowu Zhanjiang Steel’s hydrogen-based shaft furnace system project, and HBIS Group’s hydrogen DRI plant with an annual capacity of 1.2 million tons for steelmaking raw materials.

Among these, the Zhanjiang project was listed as a key preparatory project in the fifth session of the 13th Guangdong Provincial People’s Congress in January 2022.

Source: Jian WU, China Hydrogen Bulletin